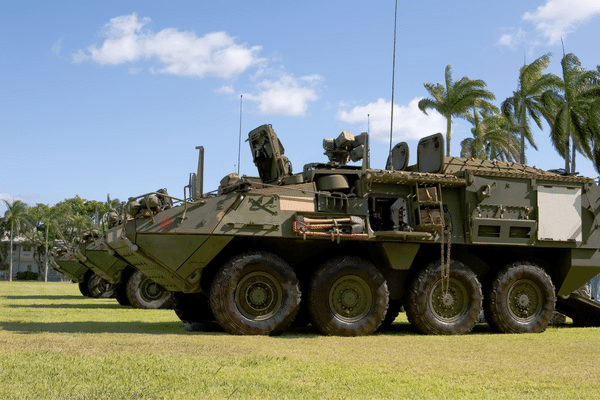

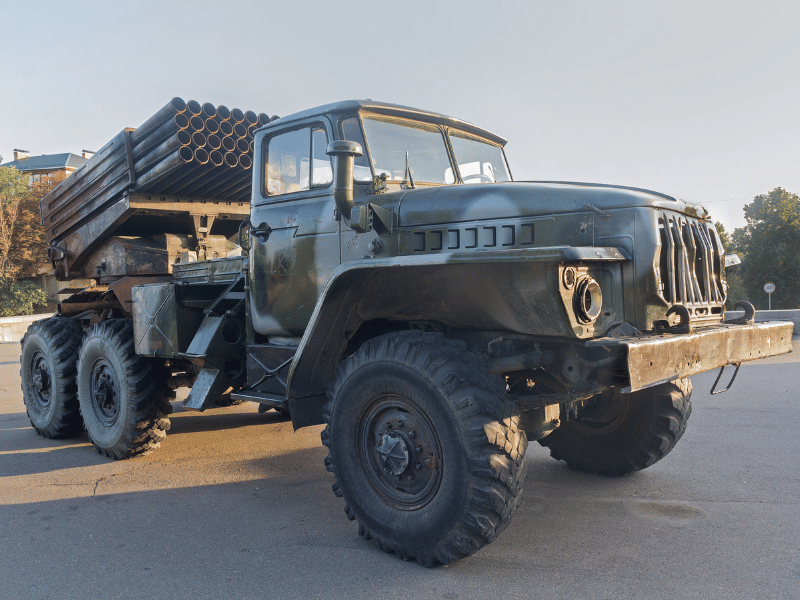

The most vulnerable part of a military vehicle is its tires. It is a vital component in the army that all military vehicles and armoured vehicles are equipped with run-flat tires. Armed forces use them to move more quickly on more hostile terrain. This mobility is an integral part of the Army’s strategic plan.

The Basic Principles of Run-Flat Tire System

Run-flat tires provide mobility to military and armoured vehicles and improve battlefield and off-road performance with a system that converts regular tires to run-flat tires. The run-flat system is bolted to the wheel rim and supports the tyre when flat, allowing the vehicle to drive up to 100 km after receiving ballistic or terrain related tyre damage. It prevents full deflection of the tire by supporting it when it gets deflated, ensuring that the vehicle continues its journey and the passengers and its contents reach a safe place.

Run-Flat Tires and Tire Changing

Compared to conventional tires, run-flat tires have stiffer sidewalls, making them harder to mount and dismount. In the past, changing a run-flat tire took over six hours, as well as extra labour-power. It also means not spending enough time for mobility in military operations due to this evolving need, GM Defensive Industries Company. Designed and produced to the army market its first generation of Run-Flat installation-removal machines. Run-flat changing machines were designed to save time, money and increase the safety of personnel.

Versions of Run-Flat Changing Machines

The Run-Flat changing machine designed by GM Defensive Industries can be used on any vehicle with a wheel size of 16 to 30 inches. This method works for changing out run-flat tires on all armoured vehicles within the warfare arsenals of the armed forces, police departments, national guard units, and any that are utilized globally. Three types of run-flat changing machines are currently available.

The standard version features 2 retractable grips with a hydraulic piston-cylinder system and 1 pusher-puller mechanism. It is used for removing and reinserting the light metallic ring on the run-flat tire to hold it in place and split the sidewall of the tires. The tire installation, removal and ring removal can be controlled using a joystick-driven controller unit. It lifts the tire with a hydraulic system for a maximum payload of 500 kg and works with a minimum pressure of 250 bars.

A container version of the run-flat changing machine is installed in a 20-inch container with a valid international transit certificate. Its principle of operation is the same as the standard version, but its design is more compact. The system operates by supplying power from generators, making easy the transportation of army forces to the operation zones, including Sharan deserts and battlefields that give the advantage of mobility.

Run-flat change machines in trailers are based on the same concept as those used in containers. With this version, run-flat changing takes place on a trailer, and it provides greater mobility than the other versions. Defence strategy relies heavily on effective mobility, so GM Defensive Industries developed run-flat change machines designed to enhance mobility.