In military operations, time is critical, and safety is paramount. GM Defensive gives a game-changing solution: the Run-Flat Tire Changer. This machine ensures military vehicles are quickly back in action, making it a must-have for defense teams. Here’s why it’s essential:

Fast and Efficient

Save Time: Change tires in 20 minutes, not hours. Keep your fleet moving.

For All Military Tires: Fits tires from 16-27 inches. Handles up to 500 kg easily.

Safety First

No More Injuries: Forget the risks of manual tire changing. Our machine is safe.

Advanced Safety: We’ve built in top safety features to protect your team.

Global Leader

Trusted Worldwide: GM Defensive leads in run-flat tire changers, with a presence in 28 countries.

Proven Expertise: Armies across the globe, including the U.S. and UAE, rely on us.

Versatile for Any Mission

Models for Every Need: Workshop, container, or trailer models. Pick what suits you.

Full Support: From buying to operating, we’re with you. Our team ensures you’re satisfied.

Critical in Operations

Keep Moving: Our changer is key for vehicles hit in battle. Get them running fast.

Gain an Edge: Your fleet is ready faster, giving you an advantage with our machine.

Top Quality and Innovation

Quality Promise: We stand for excellence. Our machines mean reliability and efficiency.

Always Innovating: We keep improving. Our changers meet the toughest military needs.

The Importance of Run-Flat Tire Changers in Military Operations

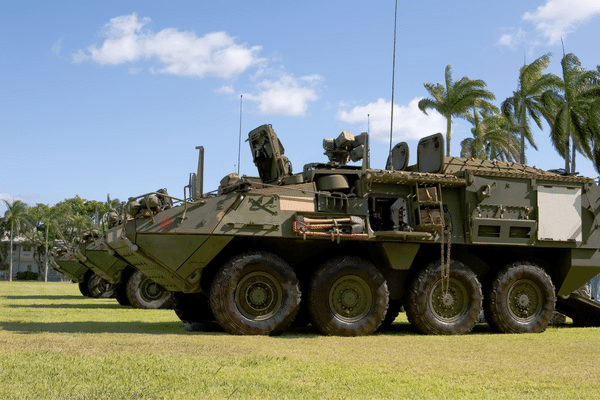

Essential for Readiness: In military scenarios, every second counts. The ability to quickly and safely change damaged tires in the field is not just a matter of convenience; it’s a crucial component of operational readiness.

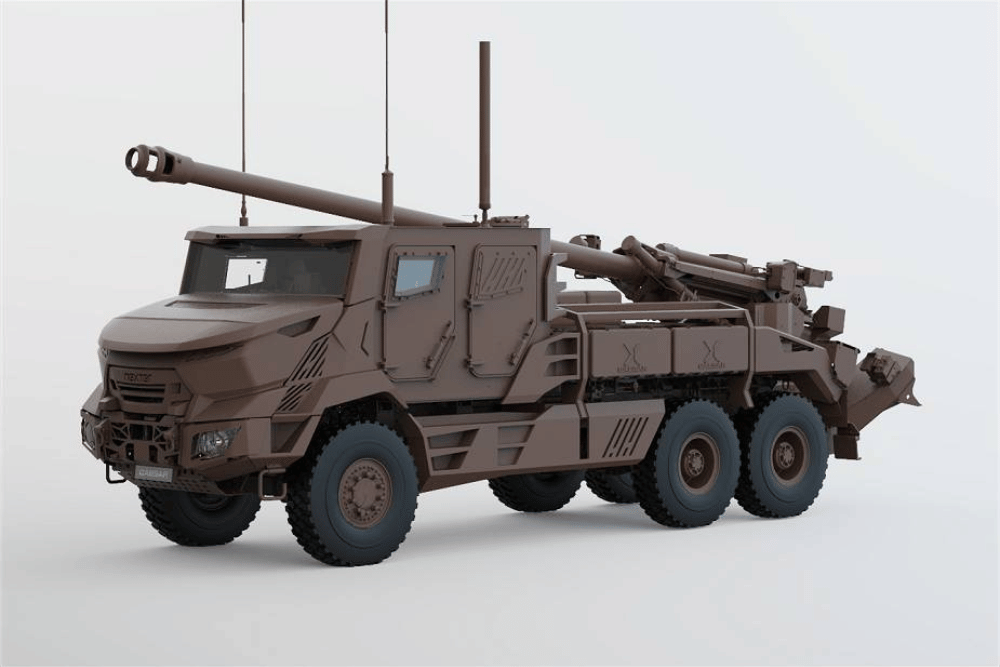

Run-flat tires, designed to function even when punctured, are indispensable for maintaining mobility under fire or after encountering hazards. Our Run-Flat Tire Changer ensures these vital tires can be replaced or repaired swiftly, minimizing downtime and keeping vehicles in the fight.

This capability is vital for maintaining the momentum of military operations, ensuring that armored vehicles can continue their mission with minimal interruption. The reliability and speed of our Run-Flat Tire Changer are why defense forces worldwide depend on it to maintain their edge in operational effectiveness.

Why Choose GM Defensive

Picking GM’s Run-Flat Tire Changer means more than just getting a new machine. It means your military tires are in the best hands, and your vehicles are ready faster and safer. It’s a smart move for any defense team looking for an edge.