Hvordan fungerer det?

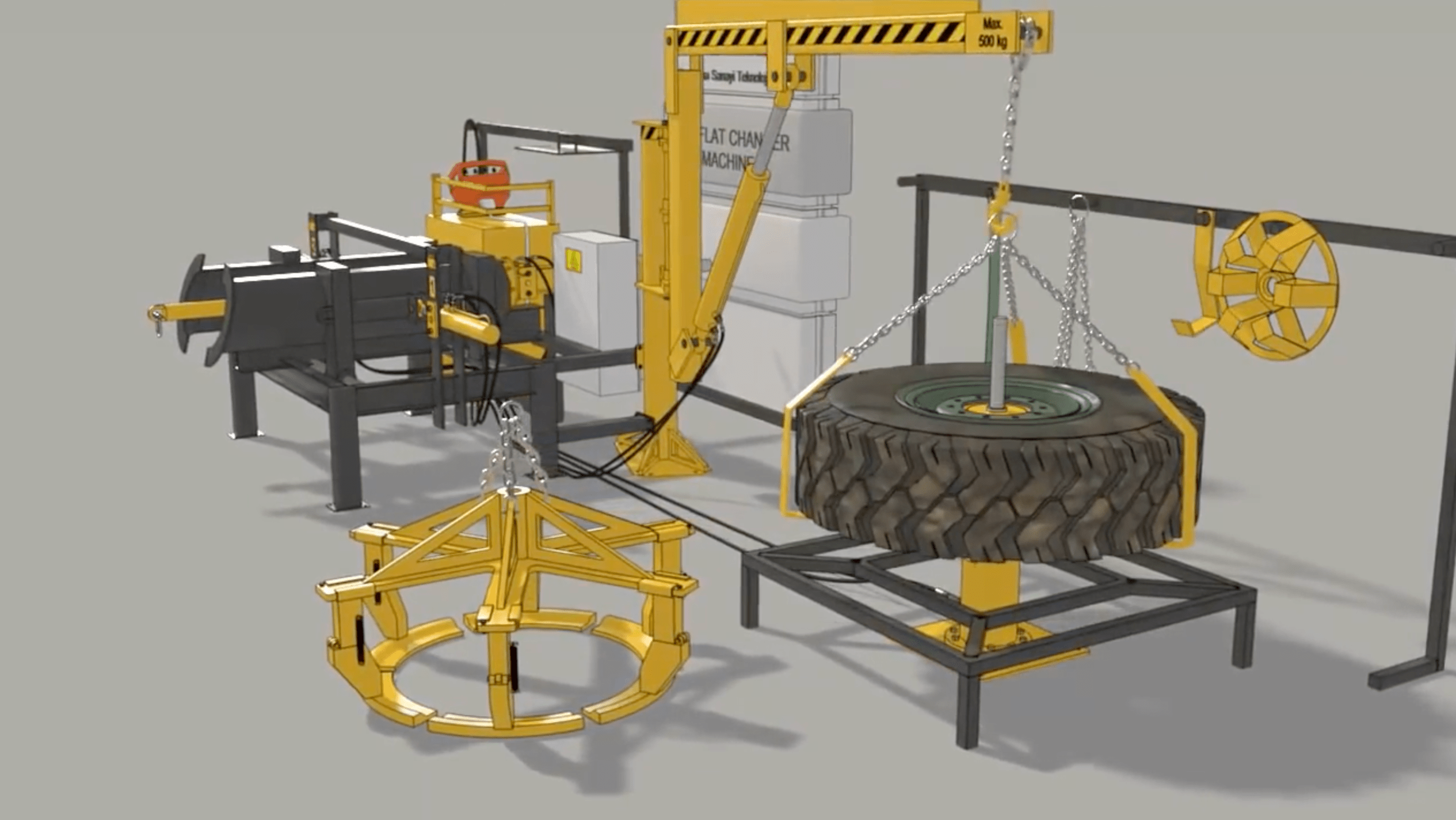

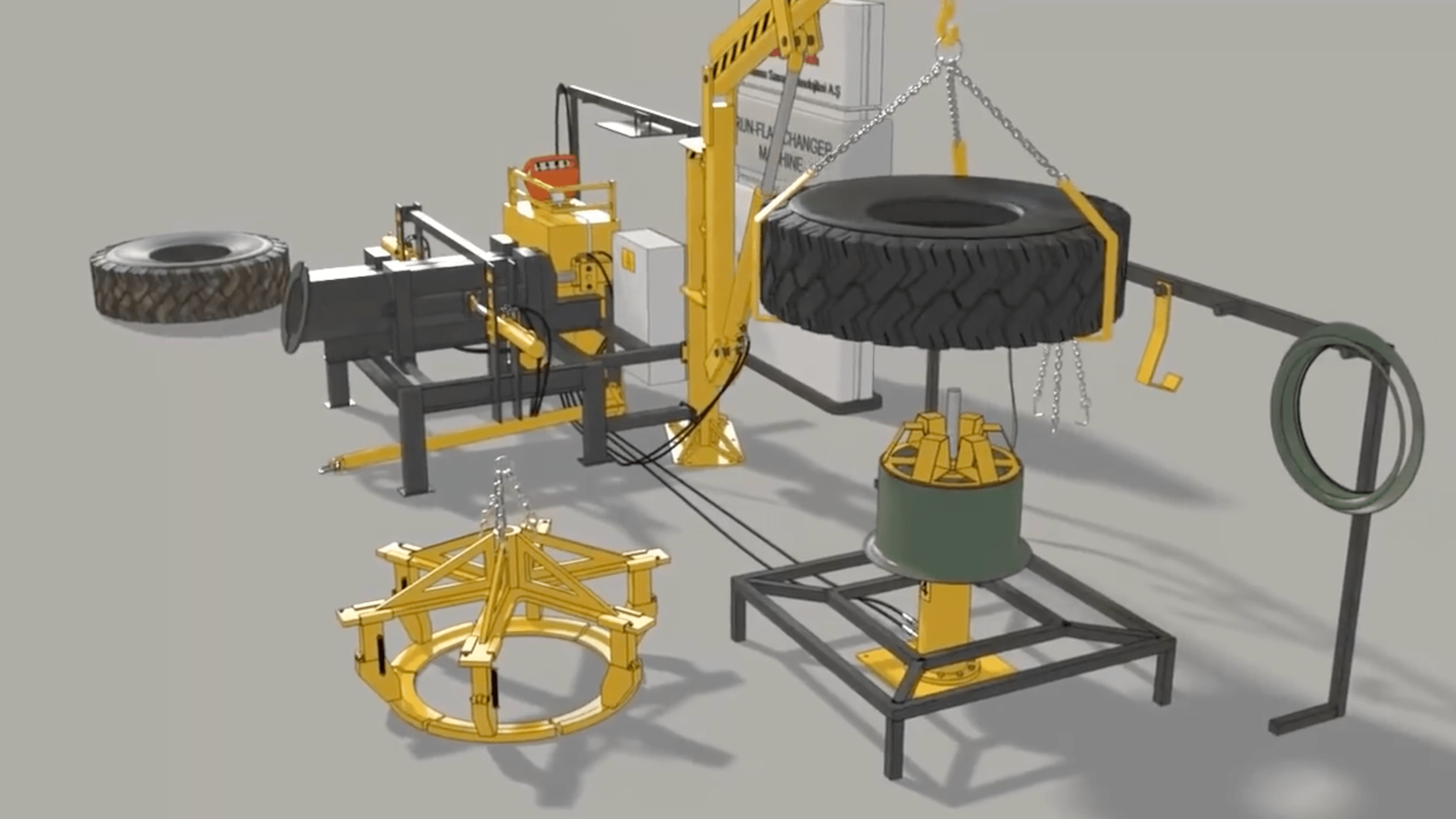

Military vehicles require specialized run-flat machines for their military tires. GM Defensive’s run-flat changer machines are designed to save time, effort, and costs by streamlining the military tire installation and removal process.

We will explore the inner workings of a run-flat changer machine and how it can revolutionize tire maintenance for military and armored vehicles.

Remove Split Rim Wheel

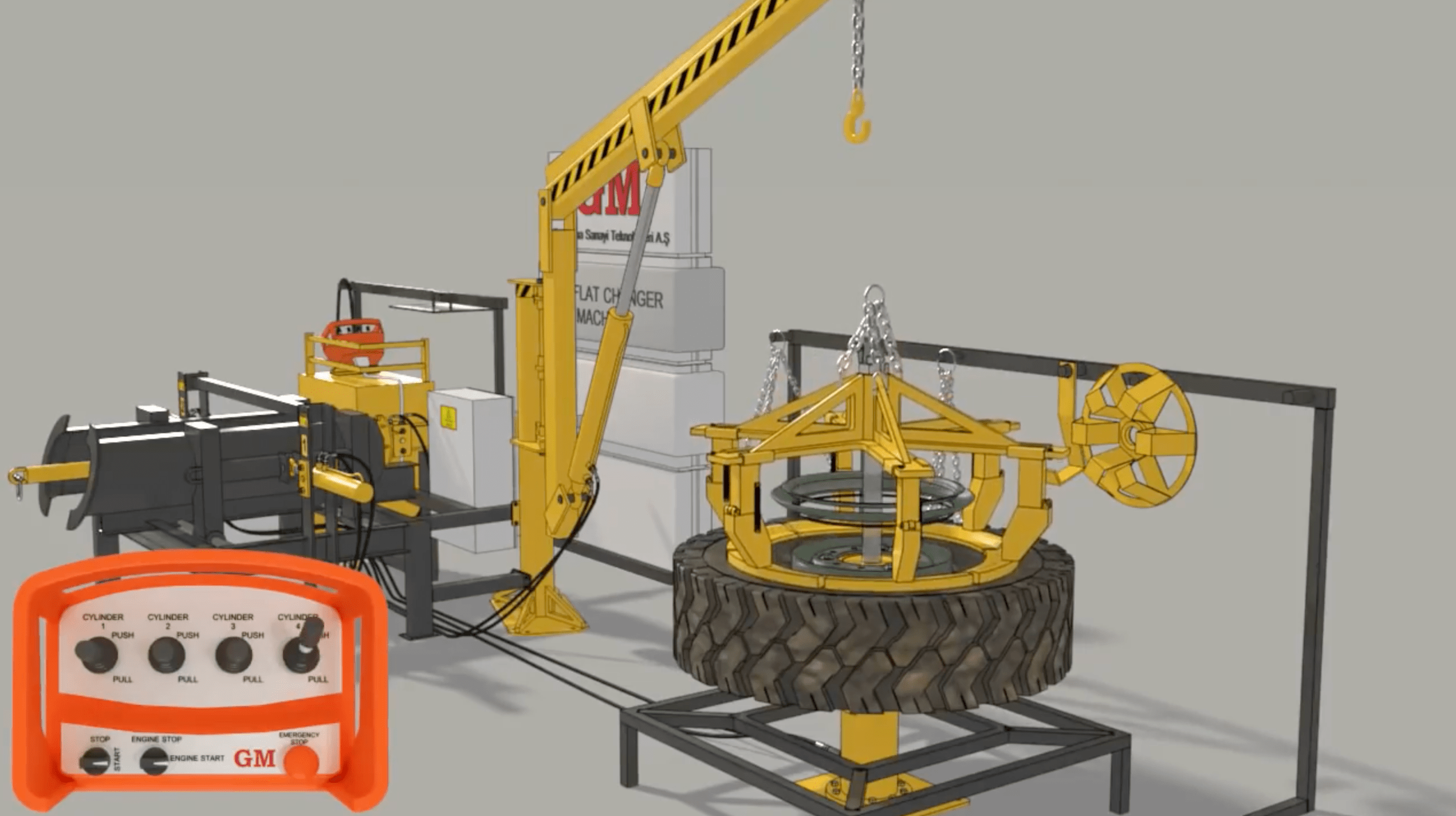

Place the Run-Flat Tire into the Ring & Rim remover (remote)

Disassemble the Flange and Locking Ring & Rim (remote)

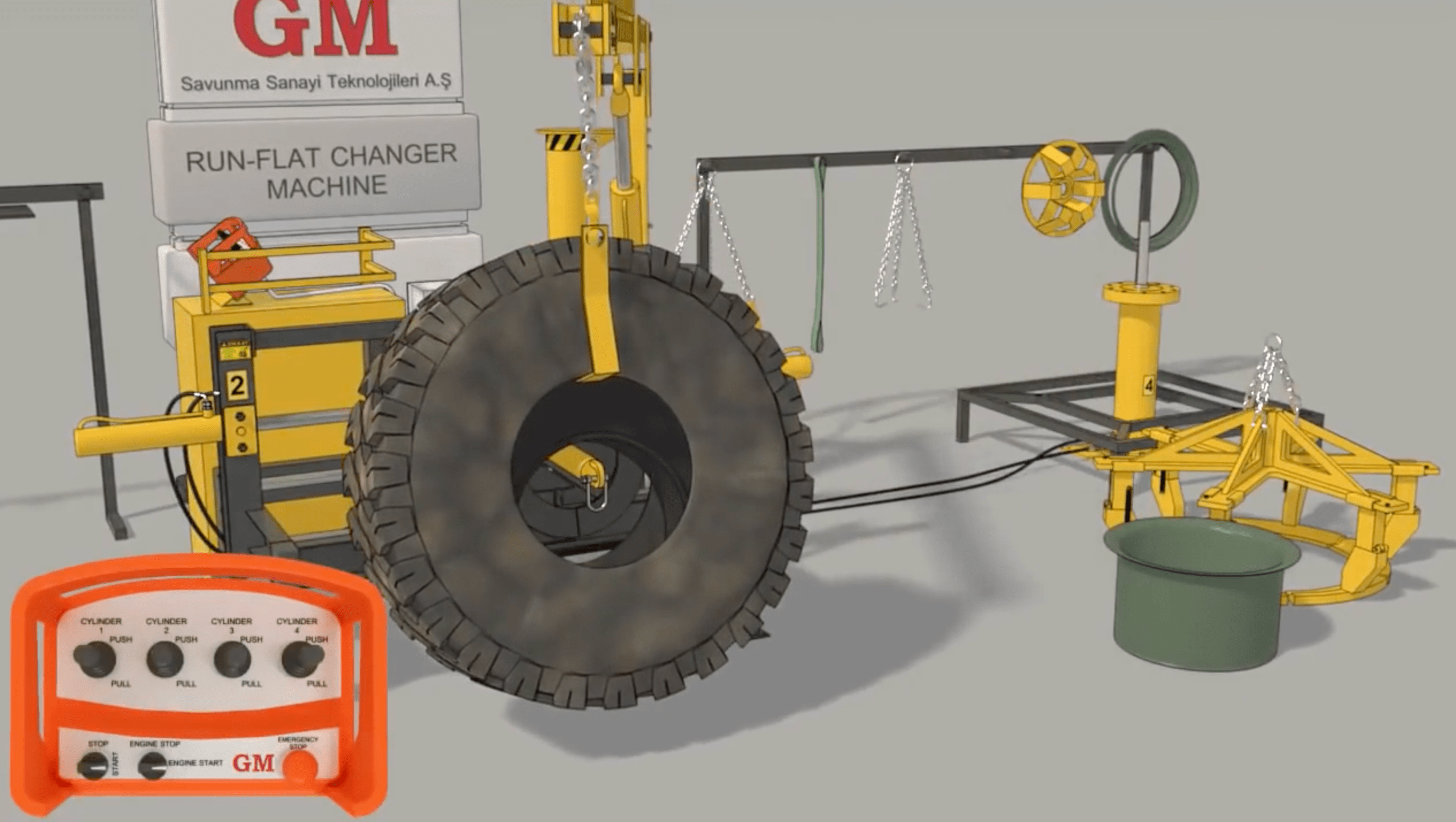

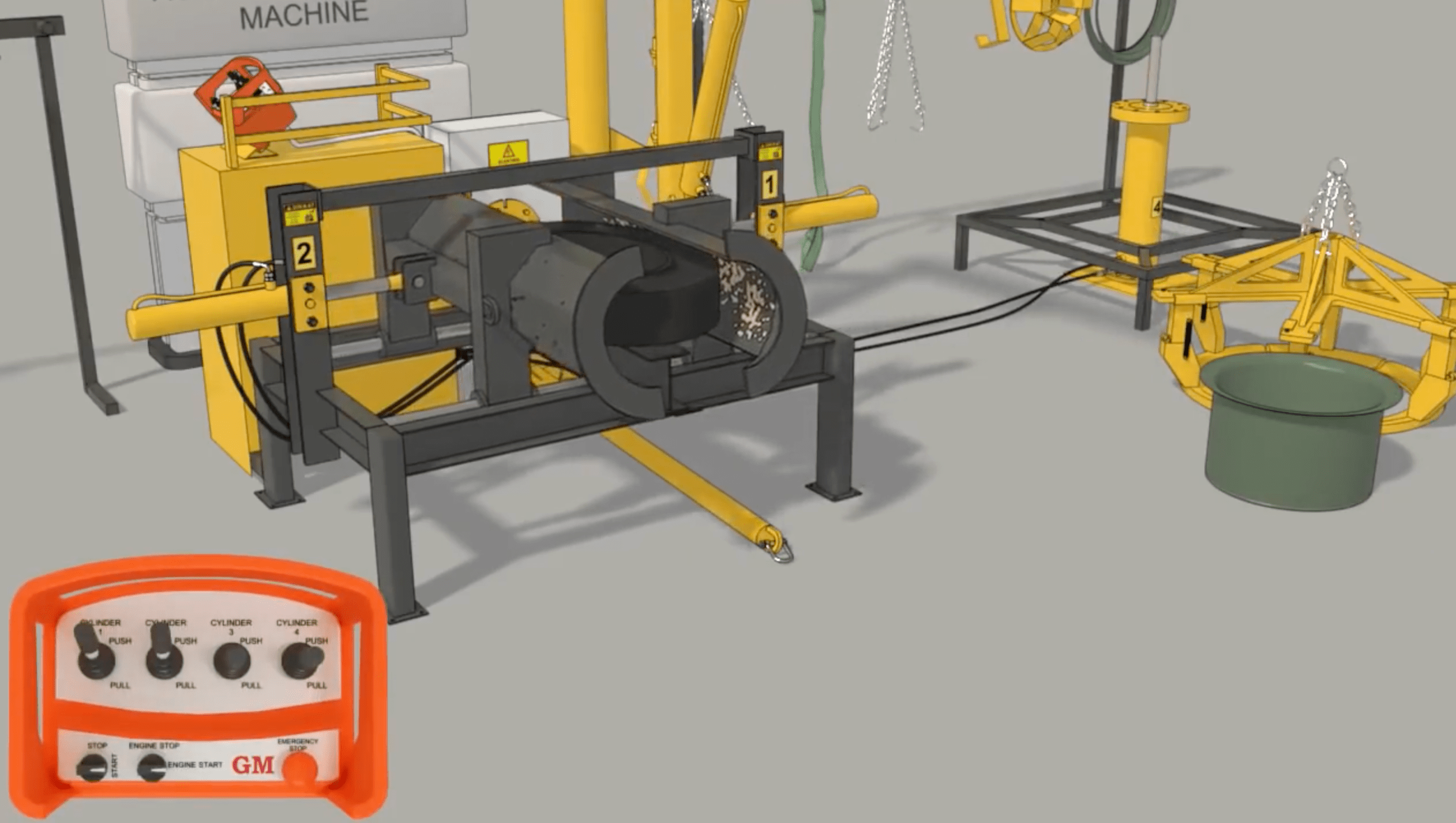

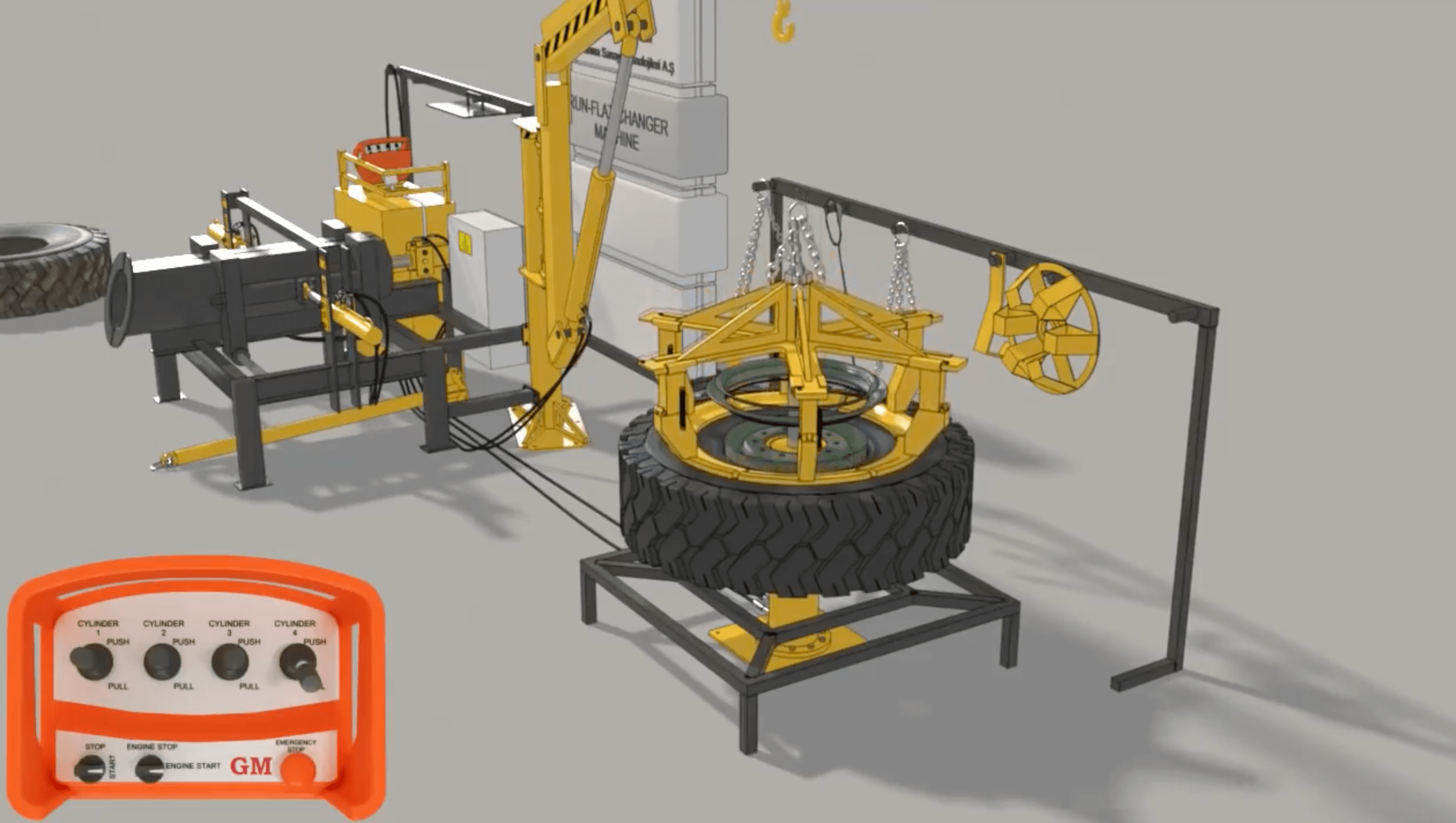

Place the Run-Flat Tire on the run-flat changer machine (remote)

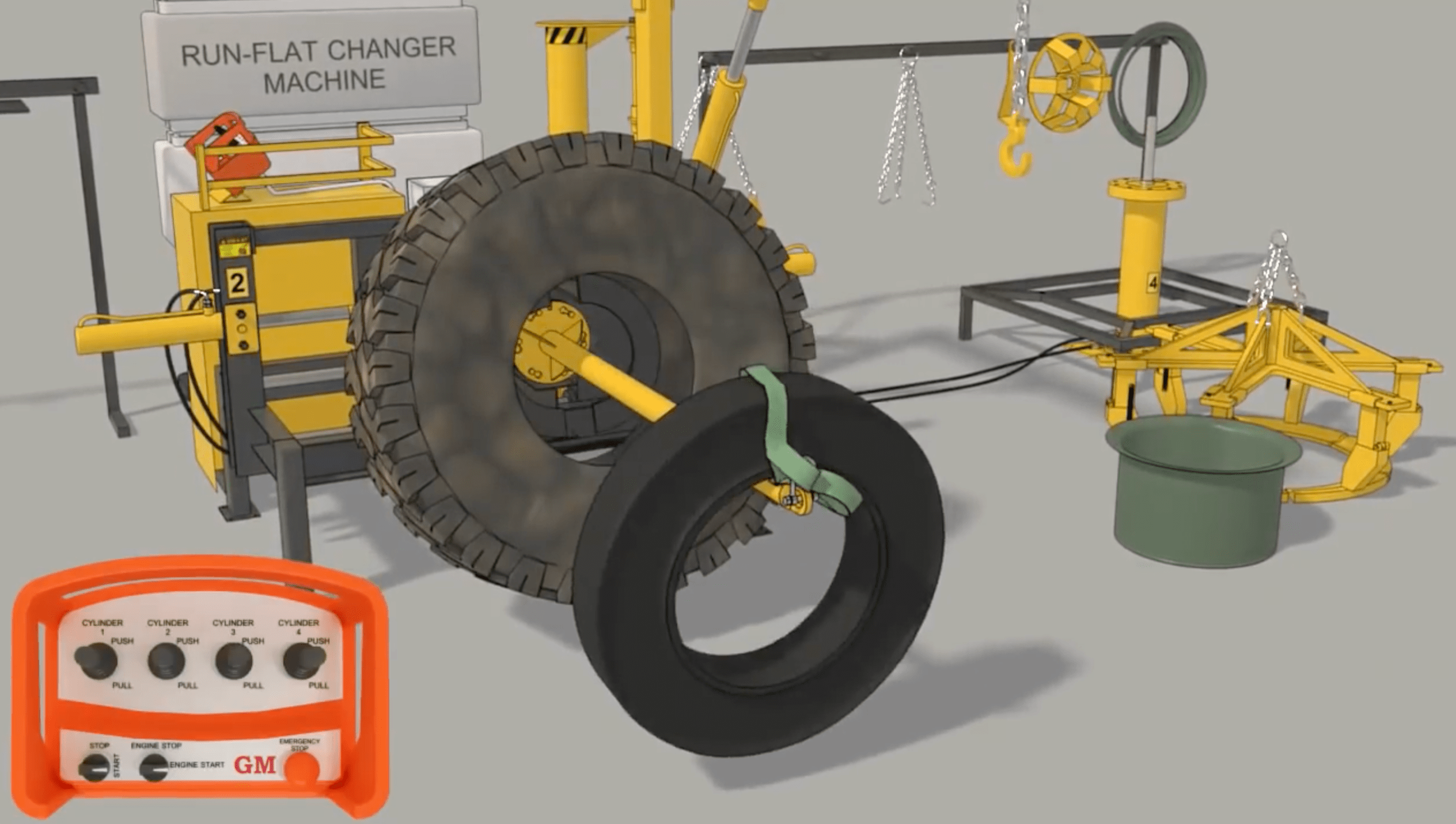

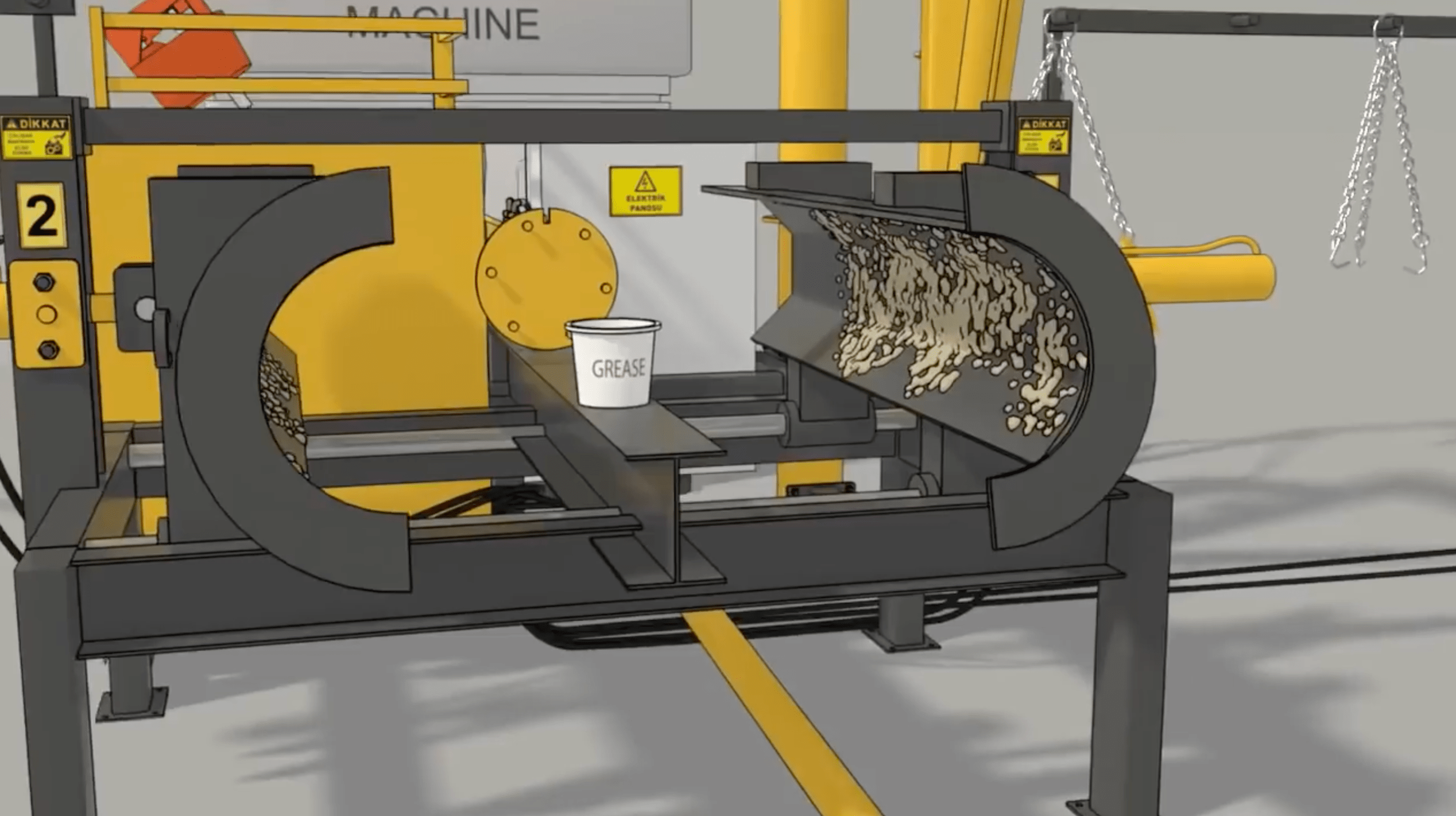

Remove the run-flat from the tire (remote)

Run-Flat TIRE Installation

Prepare the cylinder tube to install the run-flat system

Place the run-flat into the cylinder tube

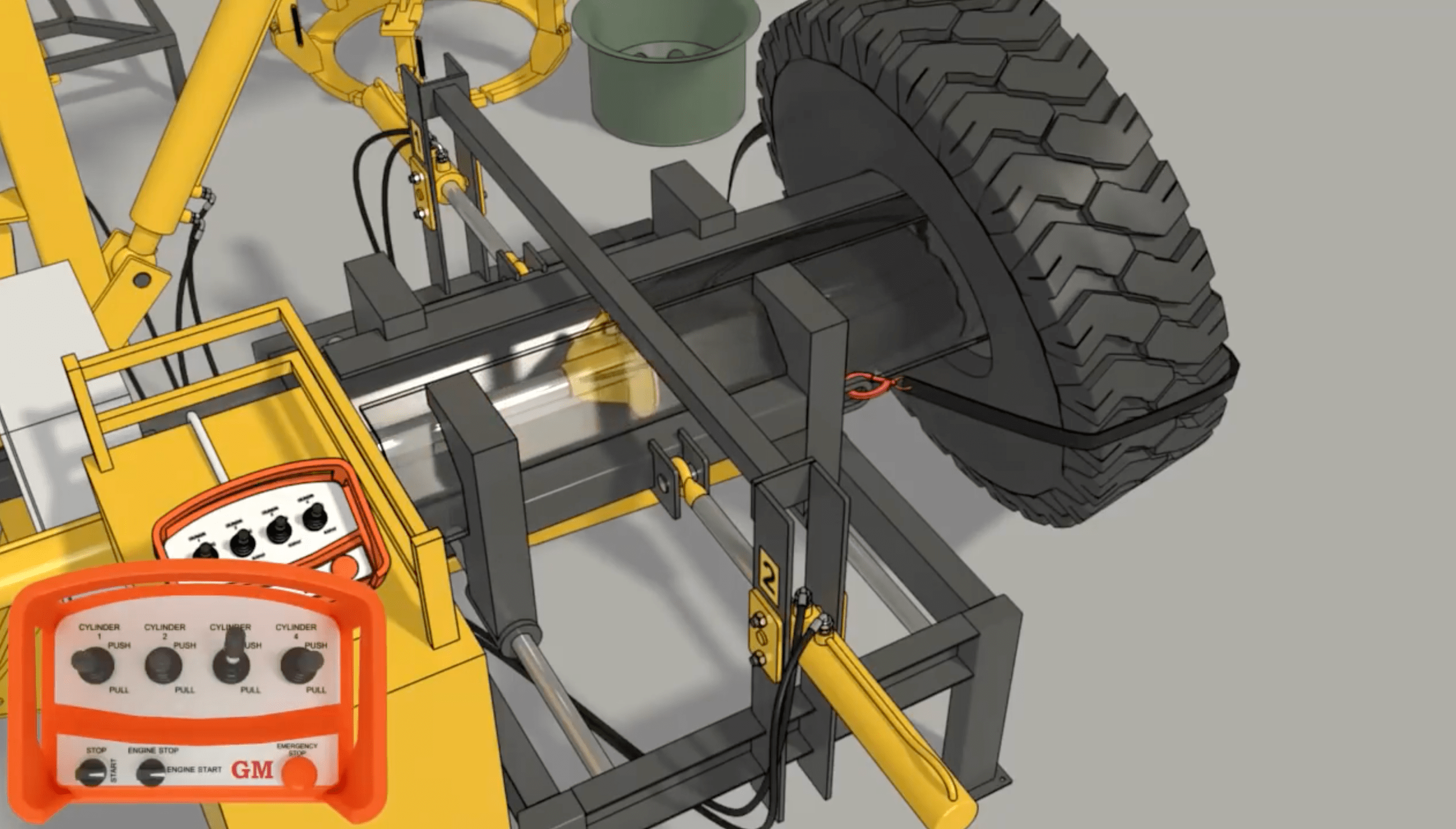

Place the new tubeless tire on the run-flat changer machine (remote)

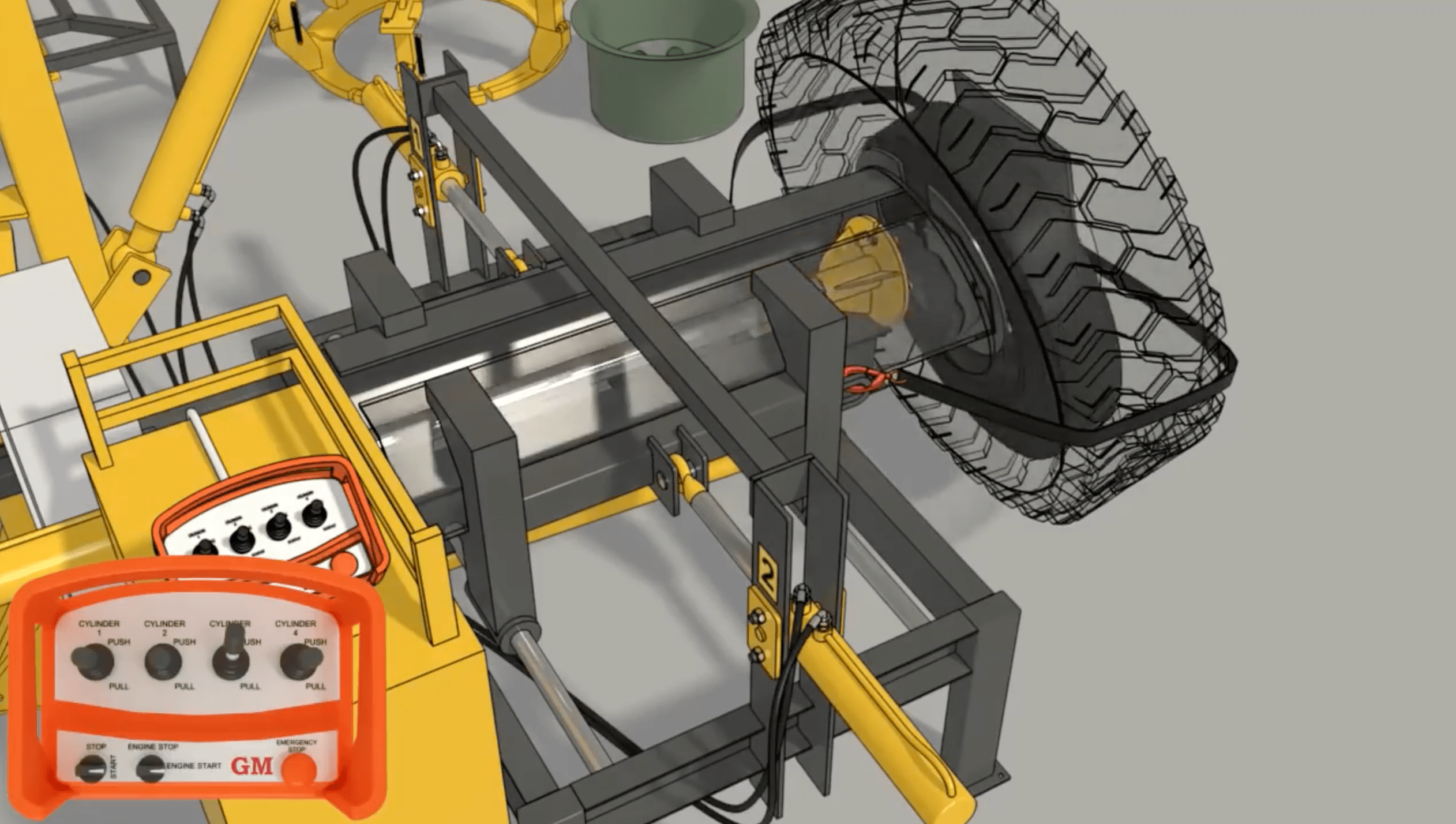

Install the run-flat into the new tubeless tire (remote)

Military Split Rims Installation

Place the Run-Flat Tire into the ring&rim inserter (remote)

Reassemble the Flange and Lacking Rings & Rim (remote)

Installation and Training Services for Run-Flat Tire Changer Machine

At GM Defensive, we strive to ensure that our customers are confident in using our run-flat tire changer machines. To achieve this, we provide comprehensive installation and training services to make the process smooth and hassle-free.

Run-Flat Changer Machine Installation Service

Our expert team will handle the installation of your run-flat tire changer machine at your facility. We ensure that the machine is safely set up, properly connected, and in optimal working condition. After completing the installation process, our 2-year warranty period begins, offering you peace of mind.

Training Service

GM Defensive is dedicated to assisting our customers. We want to ensure they have the right knowledge and skills to use our run-flat tire changer machines. This will enable them to use the machines effectively. We offer personalized training sessions.

3 Run-Flat Tire Machine Models GM Defensive Produce

Mobile trailer model designed for military personnel in operation zones.

Comes with a 20-foot storage container and trailer for mobility.

Equipped with an air conditioner for a comfortable working environment.

Compact and mobile machine that fits into a 20-foot container.

Designed for easy transportation in various military operation zones.

Air conditioner included for a comfortable working environment.

Ideal for organizations that do not require relocation.

Offers adaptability for vehicles with unique tire configurations.

Compatible with a broad range of military vehicles.

Common Features of All 3 Run-Flat Tire Machine Models

All three military run-flat changer machine models share the following features:

Run-Flat Removal:

Efficiently and safely extract run-flat systems from heavy-duty tubeless tires utilizing safety ropes and hydraulic cylinders.

Split Rim Wheel Replacement:

Designed for multi-piece wheels, this process simplifies the removal and installation of the locking ring, ensuring the tire is securely fastened.

Run-Flat Installation:

Quickly and securely install run-flat inserts into military-grade tubeless tires.

Heavy-Duty Tire Lifting System:

Easily maneuver tires with a complete wheel using a remote-controlled crane system.

Remote Control:

The run-flat changer machine is equipped with dual control devices – a joystick mounted on the main machine and a remote control. Both devices feature emergency buttons for added safety.

SAVE TIME (20 MIN)

LABOR SAVING

SAVE MONEY

SAFE DRIVE

AUTOMATION

WORKPLACE SAFETY

Time-saving: Complete tire maintenance in just 20 minutes

Labor-saving: Reduce manpower required for tire maintenance tasks

Cost-effective: Minimize costs with efficient tire assembly and disassembly

Automation: Simplify tire maintenance with automated features

Safe Drive: Ensure vehicle safety with correctly assembled runflat systems

Workplace Safety: Reduce the risk of accidents and injuries with remote-controlled operations