If you operate military vehicles or any other type of vehicle equipped with run-flat tires, you know that changing these tires can be a challenging and time-consuming process. Military vehicles rely heavily on run-flat tires, as they are designed to continue functioning even when punctured or damaged, allowing the vehicle to complete its mission and get the troops home safely. However, this also means that changing a run-flat tire can be more difficult than changing a regular tire, especially if the tire is heavy or the rim is damaged.

This is where a run flat tire removal machine comes in. A run flat tire removal machine is a specialized piece of equipment that enables you to quickly and safely disassemble run-flat tires from the rim without having to physically lift the vehicle. This is especially useful if the tire is damaged or otherwise unable to be removed by hand. A run flat tire removal machine works remotely, making the process easier and safer.

Labor Saving with Run Flat Changer

There are several benefits to using a run flat tire removal machine for military vehicles. For one, it improves safety. Removing a run-flat tire by hand can be physically demanding and potentially dangerous, especially if the tire is heavy or the rim is damaged. A run flat tire removal machine eliminates these risks, making the process safer for the technicians who are changing the tires. Additionally, it increases efficiency.

Time Saving with the Remote Technology

Changing a run-flat tire by hand can be time-consuming, especially if the tire is heavy or the rim is damaged. A run flat tire removal machine speeds up the process, allowing you to change tires more quickly and get your vehicles back on the road. This is especially important in military operations, where time is of the essence and every minute counts. Finally, it reduces wear and tear. Changing tires by hand can be hard on the body, and it can also damage the tires and rims. A run flat tire removal machine reduces the risk of damage, helping to ensure that your tires and rims remain in good condition.

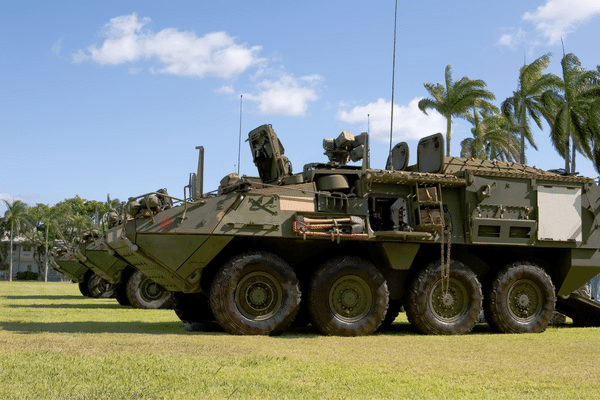

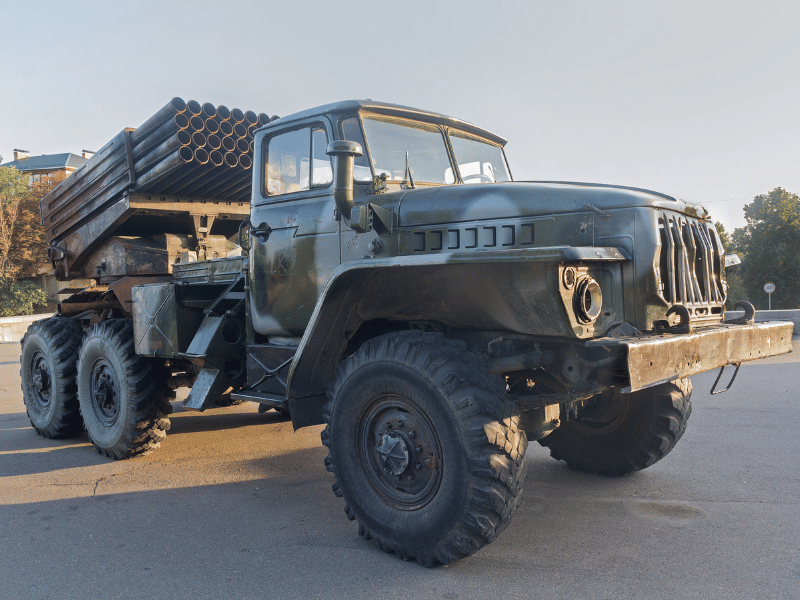

There are many different types of run flat tires used on military vehicles, each designed for specific missions and terrains. Some run flat tires are designed for high-speed operations, while others are designed for off-road use. Some run flat tires are designed to be used in extreme temperatures, while others are designed to be used in wet or muddy conditions. Regardless of the type of run flat tire you are using, a run flat tire removal machine can make the process of changing these tires easier and safer.

If you operate military vehicles or any other type of vehicle equipped with run-flat tires, a run flat tire removal machine is an essential piece of equipment for maintaining and repairing your tires. Whether you are in the military, in the transportation industry, or in any other field that uses run-flat tires. A run flat tire removal machine can make tire maintenance and repair easier and safer.

When you consider for a run flat tire removal machine, it is important to consider the specific needs of your operation. Check GM Defensive run-flat tire removal machine models. Some factors to consider include the size and weight of the tires you are working with, the type of run flat tires you are using, and the type of vehicle you are servicing. There are many different types of run flat tire removal machines on the market, each designed for specific applications, so it is important to choose the right machine for your needs.

Suitable For all Armored Vehicles with Run-Flat Tires

Run flat tire removal machine is a valuable machine for anyone who operates military vehicles or any other type of vehicle equipped with run-flat tires. It improves safety, increases efficiency, and reduces wear and tear, making it an essential piece of equipment for maintaining and repairing your tires. If you are in the military, in the transportation industry, or in any other field that uses run-flat tires, a run flat tire removal machine can make a significant difference in the way you service and maintain your tires.